Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

Whether you’re looking to buy electronic components in bulk or just a few pieces, China has the supplies you need. With a wide range of components available, you can find the perfect match for your project. From capacitors and resistors to integrated circuits and transistors, China has the electronic components you need to get the job done.

China also offers a variety of customization options to meet your specific needs. For those looking for the best deals, buying electronic components from China is the way to go. With unbeatable prices and unbeatable quality, you can rest assured that you’re getting the best components for your project.

NTC Thermistors

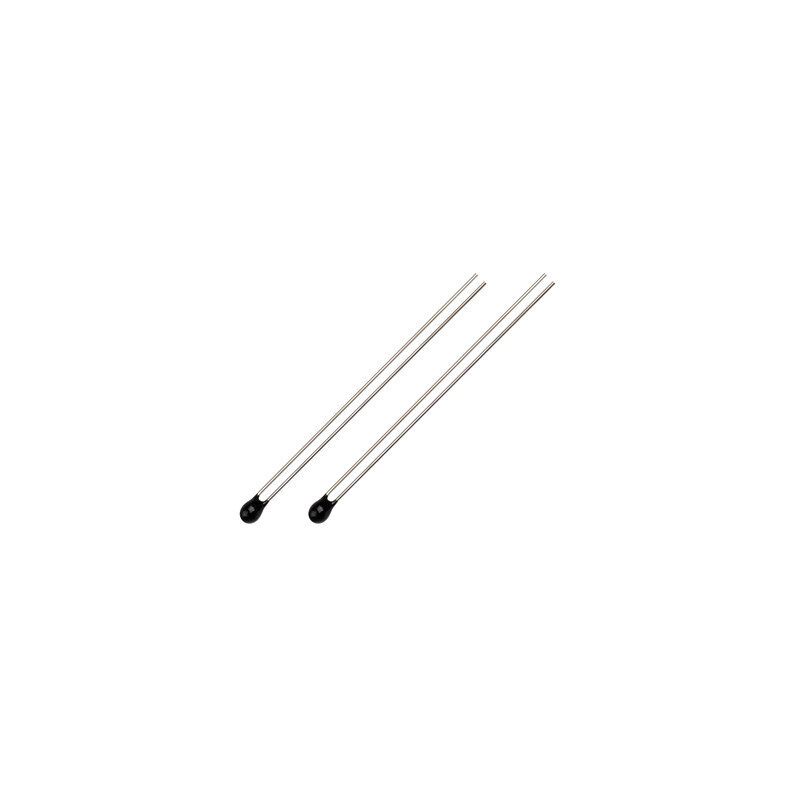

(6)MF52B NTC Thermistor

Features: *High accuracy of Resistance value and B value, excellent consistency *Fast response speed,high sensitivity *Wide resistance range: 0.1-500KΩ

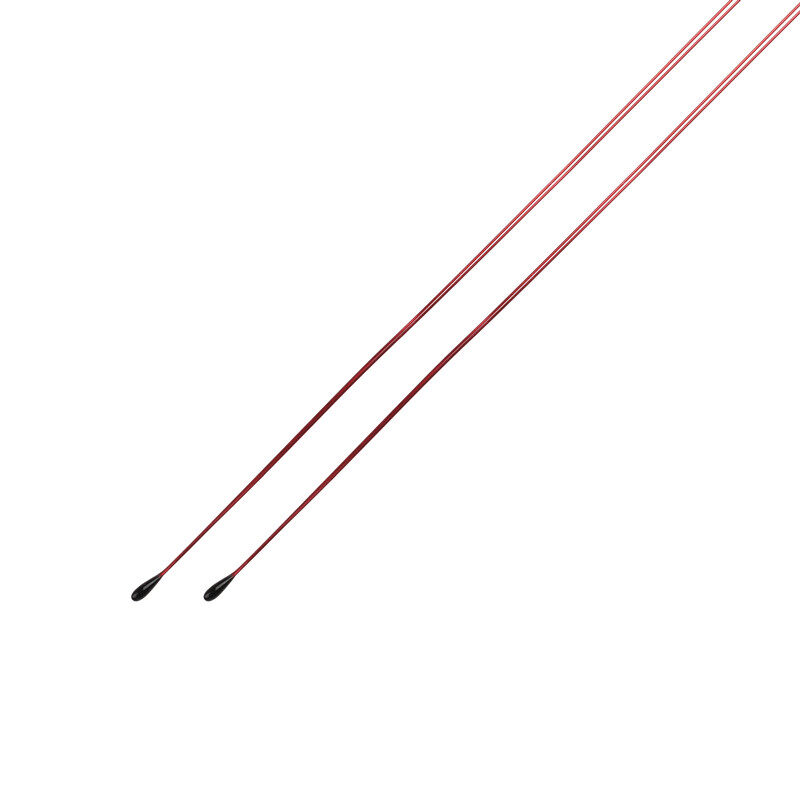

MF52E NTC Thermistor

Features: *High accuracy of Resistance value and B value, excellent consistency *Fast response speed,high sensitivity *Wide resistance range:0.1-500KΩ

MF52D Thermistor

Features: *High accuracy of Resistance value and B value, excellent consistency *Fast response speed,high sensitivity *Wide resistance range:0.1-500KΩ

MF58 Thermistor

Features: *High reliability, excellent heat resistance with glass encapsulation *High accuracy of Resistance value and B value,good stability and repeatability. *Wide range of resistance: 0.1~1000KΩ

NTC Temperature Sensor

(16)Temperature Control for Kettle

Working temperature range: -30 to 180℃ Thermal time constant: 3sec. Insulation Resistance: 500VDC≥MΩ

Induction Stove Temperature Sensor

1. NTC Thermistor 2.Resistance value and B value have high precision, good consistency, and stable performance. 3.The installation is simple and convenient, and the size can be customized according to the installation structure(OEM)

Electric Iron Temperature Sensor

Y12 this series of temperature sensors are installed by riveting and fixing. It has a simple structure and high-temperature measurement sensitivity. Various dimensions can be customized according to customer needs, which is convenient for customers to install according to the structure, and customize or match various characteristic parameters according to customer needs. This series The product has stable and reliable performance and good temperature measurement consistency.

Temperature sensor in household appliances

This temperature sensor has good resistance of water, easy installation, high sensitivity of temperature sensing. It can be used in Kettle,Coffee machine,Water heater..etc.

Meat Probe Thermometer

(12)Weber Grill meat thermometer

BBQ probe purpose: In order to judge the doneness of barbecue, a food temperature probe must be used. Without a food probe, it will cause unnecessary stress, because the difference between uncooked food and cooked food is only several degrees.

Best BBQ Smoker Thermometer

Using a food temperature probe can greatly help you understand the temperature peaks intuitively, ensuring that all your food tastes delicious and is cooked to the level you want.

Best barbecue meat thermometer

BBQ probe purpose: In order to judge the doneness of barbecue, a food temperature probe must be used. Without a food probe, it will cause unnecessary stress, because the difference between uncooked food and cooked food is only several degrees.

Digital meat temperature probe

Master the art of precision cooking with the instant read kitchen thermometer, an essential tool for any culinary aficionado. Designed to deliver quick and accurate temperature readings, this kitchen thermometer probe is perfect for ensuring your dishes are prepared to perfection, whether you’re baking, grilling, or candy making.